Usually, we go through life without giving ordinary things a second thought, and paint is sometimes considered so. But I would argue that paint and its ability to bring so much beauty into our lives is anything but ordinary. With so many different types of paints and colors, we might be asking ourselves how is paint made and what goes into it. Luckily, here at We Paint Texas, we know a thing or two about paint, so we can give you the answers you’re looking for. Follow along and discover the secrets of that paint you see brightening up your home, your business, and your life.

The Fascinating History of Paint

The history of paint dates back to prehistoric times when early humans used natural pigments mixed with various substances to create rudimentary paints for cave art and body decoration. Over time, civilizations advanced the paint-making process, experimenting with new pigments and binders, such as gum arabic – used for watercolors – and egg whites. In ancient Greece and Rome, artists further refined paint-making methods, introducing toxic pigments like lead white and vermilion, as well as encaustic painting using hot beeswax.

Later on, during the Renaissance, the discovery of oil-based paints by artists like Jan van Eyck and Leonardo da Vinci revolutionized the art of paint-making, allowing for vibrant colors and longer working times. Paint was popular and used everywhere; however, it was with the Industrial Revolution that paint production became mechanized and standardized, leading to the development of synthetic pigments and binders, making paints more affordable and widely available, and ultimately shaping the modern paint industry as we know it today.

What Goes Into Paint?

There are various ingredients in paint nowadays, but at its core are four crucial ones:

- Pigments or Dyes – Pigments are finely ground, solid particles that provide color to the paint. They can be derived from natural sources, like minerals or plants, or synthetically produced. Dyes, on the other hand, are soluble colorants that dissolve in the paint’s liquid medium.

- Binders – Binders, also known as resins, are the “glue” that holds the pigment particles together and adheres the paint to the surface. They can be natural, such as linseed oil or egg yolk, or synthetic, like acrylics, alkyds, or epoxies. Paint properties such as drying time, flexibility, and durability are determined by the type of binder used.

- Solvents – Solvents are liquid carriers that disperse the pigments and binders, allowing for smooth application and proper drying. Common solvents include water, mineral spirits (a liquid derived from petroleum), and alcohols. These solvents evaporate as the paint dries, leaving behind the pigment and binder.

- Additives – Additives are supplementary ingredients that enhance specific properties of the paint. These can include thickeners to adjust viscosity, dispersants to prevent pigment clumping, biocides to prevent mold and mildew growth, and UV stabilizers to protect against fading from sunlight exposure.

How Is Paint Made?

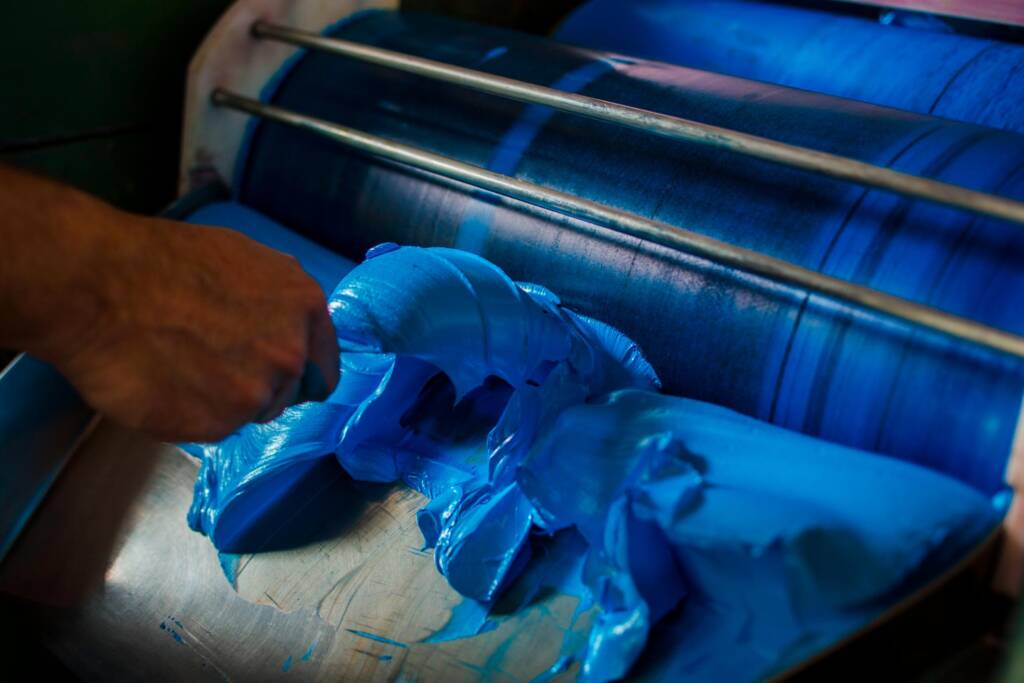

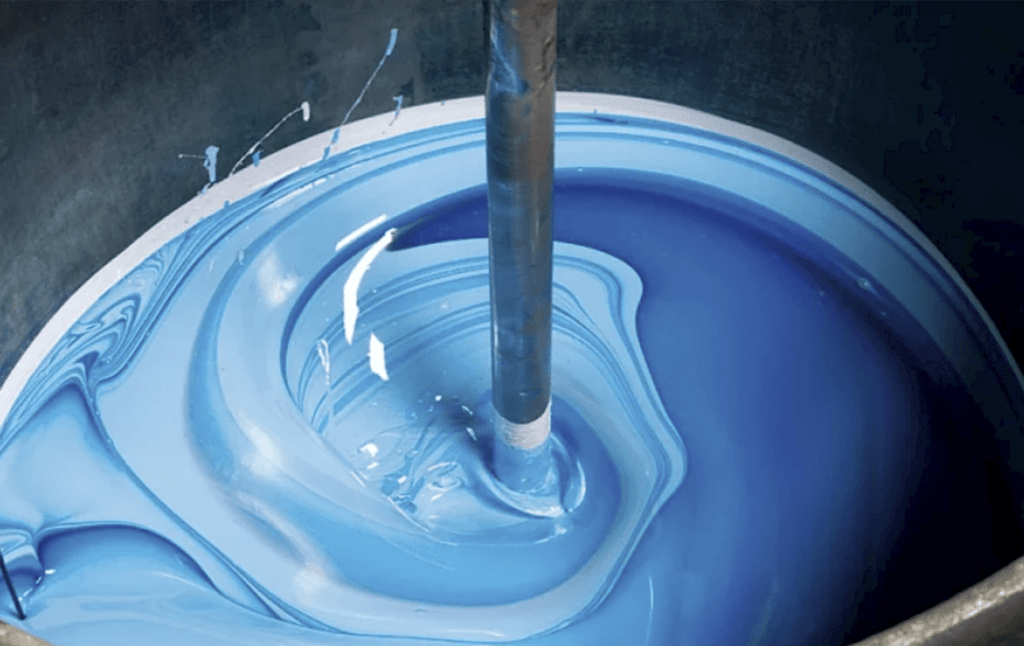

The manufacturing process of paint requires the ingredients to be precisely measured using calibrated equipment to ensure that there is accurate formulation. Pigments are broken down, dispersed, and mixed with resing and additives. Later, this mill base is combined with other ingredients in a let-down vat before undergoing quality testing for properties like dispersion, viscosity, color, and drying time.

Once the mixture passes quality inspection, it is canned and stored for distribution after a sample is retained for future reference. On an industrial scale, the production of paint requires rigorous quality control measures and specialized equipment. This production utilizes advanced technologies such as automated dosing systems and computer-controlled processes.

As with any product being handled at an industry scale, quality control measures like regular testing and inspections are enforced throughout. And manufacturers have to adhere to safety protocols and environmental regulations to ensure there is responsible material handling and disposal.

The Art of Mixing Colors

Mixing colors is both an art and a science. Experienced painters develop an intuitive understanding of how different pigments interact, allowing them to precisely capture desired tones and nuances. At the same time, there are mathematical principles and color models, such as the color wheel, that help explain the relationships between colors and guide the mixing process.

Whether working with traditional oil paints, watercolors, or modern acrylic formulations, mastering the art of mixing colors is a fundamental skill for any painter or artist seeking to express their creative vision through vibrant and dynamic hues. Or, in our case, make clients’ color dreams come true.

Special Paints and Their Applications

While standard paints are suitable for most residential and commercial applications, certain industries and environments require specialized coatings with unique properties. These specialty paints are formulated to withstand extreme conditions, provide enhanced protection, or deliver specific performance characteristics.

The automotive industry, for example, relies on paints that can provide a durable, high-gloss finish that resists chipping, fading, and corrosion and one that also protects the vehicles from factors like UV rays and extreme temperatures. Another example is the marine industry, as they need paints that can prevent rust, algae growth, and other forms of degradation. Some even incorporate biocides to prevent marine life from getting attached to boats and ships.

One of the more significant environments that require special paints are industrial ones, where surfaces are often subjected to extreme temperatures, chemicals, abrasion, and other challenging conditions. These need industrial coatings, such as epoxy, polyurethane, and intumescent paints, that are designed to protect equipment, machinery, and structures from various hazards.

These specialty paints are often more expensive than conventional paints due to their advanced formulations and specialized ingredients. However, their unique properties make them indispensable in industries and applications where performance, durability, and protection are critical.

Conclusion

The production of paint is a fascinating blend of art, history, and science. From its ancient origins in cave art to the modern industrial processes, paint has evolved through centuries of experimentation and innovation. The meticulous combination of pigments, binders, solvents, and additives, along with advances in technology, has made it possible to create an extensive range of colors and formulations that can beautify a home and also protect surfaces in demanding environments.

So, now you know how paint is made and you can show off these tidbits with your loved ones so they can all come to appreciate the craftmanship behind the extraordinary feat that paint is. You can also let them know that if their house or commercial building is in need of a fresh coat of paint, We Paint Texas will handle it. Give us a call, and we’ll give you a free estimate and the best paint job you’ll see in Texas.